TETRAClean ‘One Pill, One Pit’ Displacement System

By Kevin Crawford | Operations Manager, Completion Fluids & Services | August 26th, 2022

What Is Displacement and Why Do We Do It?

Generally, displacement simply means displacing one fluid in the wellbore with another fluid. In most cases, however, the term signifies the displacement of a solids-laden drilling fluid to a solids-free completion fluid, marking the transition from the drilling phase to the completion phase. Often, the operation entails pumping into the wellbore several clean-up ‘pills’ large enough to keep the drilling and completion fluids apart. These clean-up pills are pumped at the highest possible rate to induce the turbulent flow necessary to clean surfaces but not so turbulent they cause mixing. They must also be sized for optimal contact time to dislodge and carry to the surface all the solids. These factors are even more acute in highly deviated wellbores to ensure all solids are removed from the low side and the casing walls are free from containments and rendered water wet, conditions necessary to run and set completion assemblies and production packers.

Displacement Methods

An indirect displacement entails the use of an intermediary fluid ahead of the completion fluid, normally seawater in offshore operations. If the intermediary seawater does not include a clean-up system, then a clean-up pill is pumped in afterward to yield the solids-free, water-wet conditions necessary for the subsequent introduction of completion fluid.

By contrast, a direct displacement accomplishes the task without an intermediary fluid. The drilling mud is displaced with a clean-up system and the completion fluid in a single circulation. Direct displacements are more efficient than their indirect counterparts because they reduce rig time for pumping (no intermediary fluid), generate less waste (no contaminated seawater), and better maintain overbalanced wellbore pressure throughout the operation, which helps reduce the influx of reservoir fluids and the potential for a kick or blowout.

Displacement Systems

Displacement systems can be single-stage or multi-stage, and TETRA offers both. As the name implies, a single-stage system is a single pill with all the necessary clean-up surfactants and suspension polymers to disperse, suspend, and remove the solids in one sweep. A multi-stage system typically entails a train of three or four pills—an initial viscosified push pill followed by one or two cleaning pills and lastly another viscosified pill. Across the industry, well conditions, mud composition, and other factors have historically determined which type of system is used.

The TETRAClean ‘One Pill, One Pit’ Displacement System

Because pit volume is a scarce commodity on offshore platforms, in the Eastern Hemisphere, TETRA has been using a novel single-stage technique, a ‘one pill, one pit’ TETRAClean displacement system that performs as well as some multi-stage systems. It was designed for maximum efficiency where pit volume is limited and rig time dear.

As with wells, every application is unique. Each job begins with detailed planning and pilot testing in our lab facilities. After we evaluate the relevant well parameters, drilling-mud properties, and rig capabilities, we calculate the optimal pill size and concentration levels. The system is then tested in the laboratory to confirm cleaning efficiency over the designed contact time.

Displacement pill volume is determined by the wellbore’s depth and volume. When pumping the pill into the wellbore, we recommend a minimum annular velocity in the range of 300 feet/minute to induce the turbulent flow needed for scouring away and suspending the solids, with an optimal contact time of 10–14 minutes. The elevated annular velocity has the added benefit of reducing the timeframe of the displacement operation.

For both monovalent and divalent brines, the TETRAClean pill is blended with a volume of working brine that has been viscosified with TETRA BioPol™ L or TETRAVis™ L viscosifier. A yield point of more than 50 lb/100 ft2 is recommended for the viscosified pill, followed by the addition of an appropriate amount of TETRAClean 205.

Benefits of the ‘One Pill, One Pit’ System

The TETRA ‘one pill, one pit’ system has proven very effective even in cases where one might expect a multi-stage system is warranted. To enumerate the key benefits, the system:

- requires less pit capacity, a scarce commodity on offshore platforms;

- enables elevated annular velocity pumping rates to yield optimal clean-out and reduce rig time;

- is compatible with all clear brine fluids and can be used to formulate a weighted clean-up pill to maintain wellbore stability;

- is effective at cleaning pits, lines, and surface equipment prior to receiving clear brine fluids onsite; and

- can be used for abandonment operations and pumped neat to aid in removing contaminants from tubing in situ, greatly reducing handling times at surface.

The Numbers Speak for Themselves

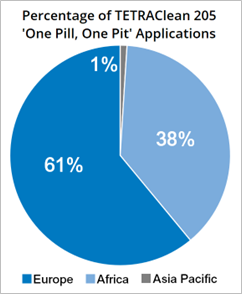

Since its introduction, the TETRAClean ‘one pill, one pit’ system has yielded excellent results in more than 640 wells and eliminated the need for additional clean-up pills. Initially formulated with a blend of TETRAClean 105 and TETRAClean 106 that was used in more than 400 wells, the system now consists of TETRAClean 205, which was introduced in 2012 and has been used in some 240 wells. Its track record of success continues to grow. The TETRAClean displacement system has even earned a gold ‘CHARM’ rating (Chemical Hazard and Risk Management) by the United Kingdom’s Centre for Environmental, Fisheries, and Aquaculture Science (Cefas).