Sand: Both Remedy and Poison

By Adam Calvin | TETRA Director of Field Engineering | October 27th, 2023

In the fields of engineering and medicine, striking the right balance is critical. Consider, for example, the Classical Greek term pharmakon—meaning both “remedy” and “poison,” depending on the intent, the application, and the effects.

Remedy and Poison

The pharmakon of the fracking boom is undoubtedly sand—a ‘remedy’ that yields enhanced production . . . and . . . a ‘poison’ to flowlines and equipment.

As a proppant, sand is abundant, environmentally safe, and often more effective than alternatives like walnut shells or beads of steel, glass, or plastic.

Yet, the sand that accompanies hydrocarbons out of the formation and wellbore can plug and erode flowlines and production equipment, each year costing the industry millions of dollars in repairs or losses. Sand can even damage the wellbore and casing beyond a critical threshold, leading to the premature demise of very productive, highly profitable wells.

Removing the sand from the production stream is therefore a basic necessity. For years this has been done primarily with gravity separators or filtration systems, but both have serious downsides: they can impose back-pressures that lower production volumes, and they require round-the-clock, hands-on maintenance—manually emptying separators and changing filter screens.

An added weakness of gravity separators is the poor efficiency that usually necessitates a series of bulky units to capture all the sand. The increased hands-on maintenance demanded of both systems also elevates both exposure to risk for personnel as well as the cost of more labor.

Reaping the Whirlwind

A far better solution for sand control is the hydrocyclone, an innovative device that uses centrifugal force to separate fine solids from fluids.

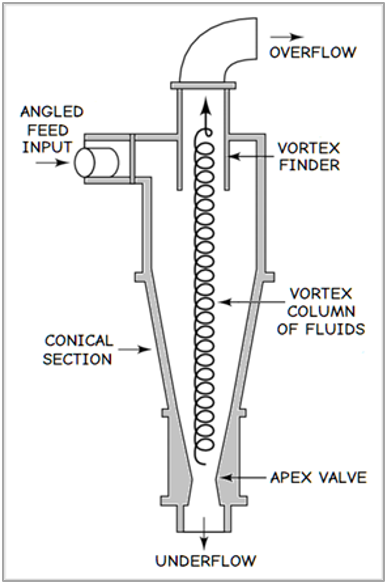

Looking at the diagram below, the production stream enters the device and whirls around inside while the inverted conical shape accelerates the content. The velocity is enough to generate a vortex, causing the fluids (both liquid and gas) to concentrate into a rising column in the center and the heavier solids to fly outward against the inner wall and travel down; the fluids exit the overflow at the top while the solids exit the underflow at the bottom.

A hydrocyclone has no moving parts, exploiting as it does the velocity of the production stream to generate the centrifugal force. The passive design virtually eliminates mechanical failure and constant hands-on maintenance, but its simplicity as illustrated in the diagram is deceptive.

A lot of precise engineering is required to make a hydrocyclone effective and reliable at sand management—again, balance is critical. Key factors include the device’s size relative to the angle of the conical section, the sizes of the input and outflow, the placement of the vortex finder, and the metrics of the apex valve.

Not enough velocity, for example, and separation will be marginal; too much and the solid fine particles will rapidly erode the inner walls or a weakly built unit will fly apart in a catastrophic failure that could cause injury to personnel. Moreover, the device must be robust enough to handle the high—often exceptionally high—pressures of oil and gas wells.

Engineering Elegance: TETRA SandStorm

A precisely engineered, super-efficient, reliable, and safe hydrocyclone now proving its value in the field is the TETRA SandStorm advanced cyclone technology. It doesn’t impose restrictive back pressures on the production stream or require constant hands-on maintenance.

In fact, the technology is easily mated with the TETRA BlueLinx automated control system for a sand management solution that not only yields sand separation efficiency as high as 99.4% but also significantly reduces labor and maintenance

We know this because in repeated applications at customer sites, TETRA SandStorm units have been set up alongside competing cyclonic traps, both with second-stage filter systems positioned downstream to capture any sands that slip through the first stage. Again and again, the filters show the TETRA SandStorm removes 97–99% of the sand from the production stream and significantly outperforms competing cyclones.

Case Study 1: Appalachia Production Rate

In the Marcellus Shale Play of Northeastern United States, an operator with a number of gas wells sought a better solution to sand recovery from frac flowback. The challenge was the very high flowrate of the wells, up to 45 MMCFD, and the varied particle size of the sand. Neither a separator nor filter system was acceptable due to their constraints on production flowrate.

The TETRA SandStorm was proposed, and at the operator’s request the technology was set up in parallel to a competitor’s. Both wells shared the same flowrate, sand volume, and sand particle size, enabling a fair, side-by-side comparison of sand recovery efficiency, impact on production flow, and time to flush the captured sands (flushrate).

The TETRA sand management system bested the competitor’s, recovering 99.4% of the sand with an unconstrained flowrate peaking at 42 MMCFD. In fact, so effective was the TETRA SandStorm that a second stage proved unnecessary and the downstream flowback incurred zero wash, thus preventing abrasive damage to the flowback and production equipment and saving the operator as much as $10,000 per well.

In addition to its unmatched efficiency, the TETRA system delivered other notable benefits. First, because it’s four times smaller than the competitor’s system, the TETRA SandStorm simplified transport and onsite placement. Second, its simple yet robust design virtually eliminated the potential for component failure, hands-on maintenance, and associated risk and downtime. And third, the time to empty the sand from the TETRA SandStorm was less than five minutes, significantly less than the 45 minutes required to flush the competitor’s system.

Case Study 2: Permian Sand Management

Another side-by-side comparison was conducted in the Permian Basin of West Texas. As with the case above, two wells were outfitted with sand management systems and downstream filters to gauge their effectiveness, but in this case the contrast was even starker.

The TETRA SandStorm hydrocyclone technology captured an average of 96.63% of the sand from 132,889 barrels of fluids, with a one-day peak of 100% and several days at 98% and 99%. By contrast, the competing desander captured an average of only 45.55% of the sand from 126,472 barrels of fluid, with a one-day peak of 60%. The TETRA solution was also twice as small as the competitor’s, so ultimately it both doubled the efficiency and cut the footprint in half.

Resolution

As with the rising volumes of produced water, sand volumes will continue to increase.

In addition to the sands we use to fracture the rock and enhance production, longer laterals and deeper, more unconsolidated reservoirs result in more sand coming out of the well. Gravity separators and filter systems will remain useful tools in certain situations, but when sand management is critical, the wisest approach is to consider the solution an investment for safeguarding equipment and production volume.

A wise investment is the TETRA SandStorm advanced cyclone technology.