Sustainable Calcium Chloride Production

By Samuel Jansson | Technical Manager, TETRA Chemicals Europe | June 12th, 2023

“The eye is the first circle; the horizon which it forms is the second; and throughout nature this primary figure is repeated without end.”

—Ralph Waldo Emerson, 1841.

Where the production of one of the world’s most widely used chemical compounds intersects with sustainable industry resides a study in remarkable innovation: TETRA Chemicals Europe’s manufacturing operation in Kokkola, Finland. Kokkola is a port city on the Bay of Bothnia, an inlet of the Baltic Sea situated between Finland and Sweden.

The chemical in question is calcium chloride (CaCl2), a salt compound used in scores of applications across a wide range of markets—from road construction and maintenance to manufacturing, oil & gas, food & beverage, and agriculture. In Finland, the calcium chloride manufacturing process is performed by TETRA Chemicals Europe at a unique facility in the Kokkola Industrial Park (KIP), a landmark installation known as the “largest ecosystem of inorganic chemical industry” in Northern Europe.[1] And while to some the terms ‘ecosystem’ and ‘chemical industry’ might seem like an unlikely pairing, the industrial park operates as what’s called a circular economy.

Circular vs. Linear

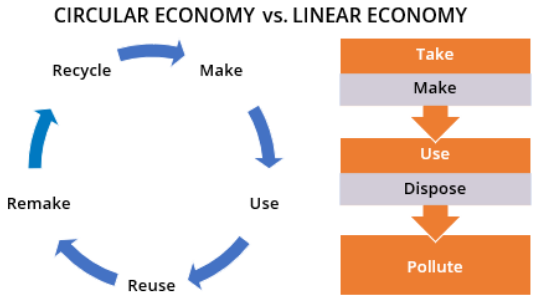

A circular economy is a holistic framework for the production and consumption of goods that differs markedly from the more traditional linear model wherein industry takes natural resources and makes products, which are then used and eventually disposed of as waste and pollution. One could in fact argue that a linear economy is inherently wasteful.

FIGURE 1. The circular economy vs. the linear economy.

By contrast, a circular economy aims to eliminate or substantially minimize waste by reusing and recycling manufactured products for as long as humanly possible. Recycling isn’t exactly a new idea; the world has been recycling paper, plastics, wood, glass, and scrap metal for decades now, as well as reusing old clothing, automotive parts, and electronic components.[2] What is unique about a circular economy is the scope and level of integration, weaving together otherwise unrelated lines of production and recycling to create a more inclusive ecosystem of deep interdependence.

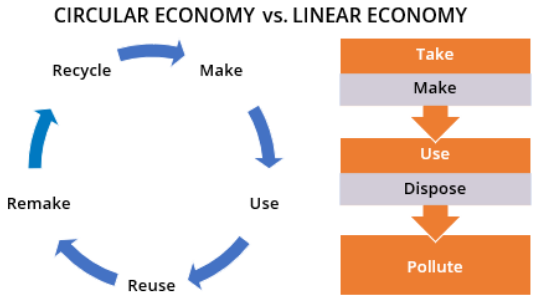

FIGURE 2. A flowchart illustrating the production of calcium chloride in a circular economy: While the production chain may appear linear here, the cascading outputs and subsequent use of chemicals, as well as the capture and sharing of CO2, constitute a less wasteful, more efficient and sustainable ecosystem emblematic of a circular economy.

Calcium Chloride Production in Kokkola

Calcium chloride is typically produced using one of four methods: [1] treating limestone with hydrochloric acid (high purity); [2] treating calcium carbonate with sodium chloride brines (low yields); [3] evaporating natural brines (low purity); and [4] as a byproduct of manufacturing magnesium oxide or dead-burned magnesia (for high-temp bricks and ceramic molds).

TETRA Chemicals Europe manufactures calcium chloride using the limestone and hydrochloric acid process to yield an exceptionally high-purity product. As part of KIP, TETRA sources hydrochloric acid from one neighboring company and sells some of its captured CO2 to another neighboring company. Additionally, the plant in Kokkola holds ISO 9001, ISO 14001, ISO 45001, and ISO 22000 certifications, and participates in the International Council of Chemical Associations’ Responsible Care initiative, which promotes continuous improvement in safe chemicals management and excellence in health, safety, and environmental performance.

FIGURE 3. An aerial view of the TETRA Chemical facility in Finland in the Kokkola Industrial Park, the largest inorganic chemical industry ecosystem in Northern Europe.

TETRA Calcium Chloride Products and Their Uses

TETRA Europe produces four high-quality variants of calcium chloride: CC tech® for industrial applications, CC food® for food & beverage applications, CC road® for road construction and maintenance applications, and CC farm® for agricultural applications. The products are available as either liquid calcium chloride or solid calcium chloride flakes in concentrations ranging from 21% to 77%.

TETRA CC tech (28%, 34%, and 36% liquid)

TETRA calcium chloride is used to purify water (by precipitating fluorides, phosphates, and sulfates), mineralize or ‘harden’ water (to prevent erosion of concrete, like swimming pools), remove moisture and humidity from ambient air, accelerate the setting time of concrete (especially in cold weather), improve the printability of paper, boost the cleaning power of detergents, strengthen plastics and latex products, and improve the performance of clear brine fluids used in oil and gas wells.

TETRA CC food (34% and 36% liquid and 77% flakes)

TETRA calcium chloride is used in the making of beers, wines, cheeses, and carbonated soft drinks, as well as to increase the firmness and shelf life of fresh fruits, canned fruits, and pickled vegetables. The compound is also added to aquariums to provide calcium to marine life with calcium-carbonate structures, like mollusks and corals.

TETRA CC road (21%, 32%, 34%, 36% liquid and 77% flakes)

TETRA calcium chloride is widely used as a de-icing agent to melt snow and ice on roads. It’s preferable to sodium chloride (common table salt) because it can melt frozen precipitation at lower temperatures and it isn’t as harmful to roadside soils, grasses, and plants. CC road is also used to control dust on gravel roads and other surfaces, including sporting grounds like tennis courts and race tracks. Additionally, calcium chloride is used in the construction of paved roads to better stabilize the underlying foundation.

TETRA CC farm (77% flakes)

Calcium chloride is a vital nutrient in agriculture. TETRA CC farm is used in fertilization and aqueous fruit drips to provide calcium to crops and reduce food storage diseases. Added to animal diets, calcium chloride helps prevent milk fever in dairy cows (caused by calcium deficiency when cows lactate), and it strengthens the bones and egg structure of chickens. It also alleviates heat stress by improving the animals’ mineral/salt balance.

FIGURE 4. Hundreds of bags of TETRA CC Road calcium chloride at the TETRA Chemicals Europe plant in Kokkola, Finland.

Salt of the Earth, Circle of Life

As one can see from our brief survey, calcium chloride is a widely used, key ingredient in an extensive range of applications. TETRA also manufactures the compound at plants in Helsingborg, Sweden, and Frankfurt, Germany, and operates distribution terminals in Sweden, Belgium, and Spain, facilitating efficient delivery across the continent and beyond. The Company is committed to producing calcium chloride of exceptionally high quality and remaining a reliable—and sustainable—supplier for many years to come.

Samuel Jansson is Technical Manager at TETRA Chemicals Europe. He has over 25 years of experience in the chemical industry including research & development, process optimization, quality assurance, food safety, and technical customer support. He holds a Bachelor of Science in chemical engineering from Lund University in Sweden.

- Kokkola Industrial Park (website): https://www.kip.fi/en/frontpage.html.

- While environmentalism has been a social concern going back to antiquity (i.e., don’t pollute the upstream water source with waste or the dead), the modern sensibility was largely spurred by ‘back-to-nature’ movements in the late 19th The more recent impetus, however, was a single image on the cover of Life Magazine in 1968: a photograph of Earth taken by US astronauts.