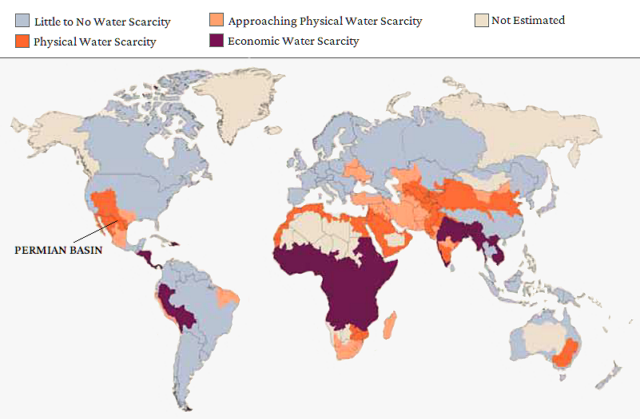

One of the biggest challenges confronting the oil and gas industry is water management, especially in unconventional operations. Hydraulic fracturing requires a lot of clean water, and for every one barrel-of-oil-equivalent, a typical operation now yields anywhere from four to ten barrels of produced water—that is water native to the reservoir itself, which is too briny for use in fracking. Ironically compounding this challenge of overabundance is the water scarcity endemic to core regions like the Permian Basin and, more generally, the entire western half of the United States. In fact, water scarcity is now considered a global problem, with water increasingly characterized as a commodity.

Recycling, ESG, and Seismicity

To meet this challenge, the most impactful innovation is recycling the produced water and flowback, carefully treating and blending it for optimal use in frac operations. Recycling is the smart choice not only because ESG—environmental, social, and governance—concerns have emerged as a major priority across every industry, but also because recycling the water is now the more cost-efficient route compared to disposing of it. Recycling reduces freshwater use, lessens roadway truck traffic to deliver freshwater and remove wastewater, and virtually eliminates disposal of wastewater in saltwater disposal (SWD) wells.

A number of factors are coalescing to make disposal of produced water less attractive: water scarcity, environmental concerns, the cost and logistics of moving millions of gallons of water, and the growing concern over seismicity associated with injecting wastewater into SWD wells.

Seismicity has, of course, been a concern among regulatory agencies in the Mid-Continent region for a few years. Now the issue is spiking in the Permian Basin, which accounts for 60% of produced-water volumes in the United States.[*] Late last year, both the Texas Railroad Commission (RRC) and the New Mexico Oil Conservation Division (OCD) signaled they’re taking the issue very seriously. New Mexico updated its regulatory framework and Texas established two seismic response areas (SRAs) to limit injection capacity and permitting in Midland, Ector, Martin, Culberson, and Reeves counties. These developments will likely entice more operators to turn to recycling.

Factors in Water Management

TETRA is at the forefront of water management in oil and gas production and completion applications, offering the full spectrum of solutions—everything from sourcing clean water to the treatment and recycling of produced water and flowback, as well as the filtration, storage, blending, distribution, and transfer. The Company engages decades-long core competencies in chemicals, chemistry, and advanced R&D to develop water treatments that are compatible with the reservoir, which is absolutely paramount for successful stimulation and the life of the well.

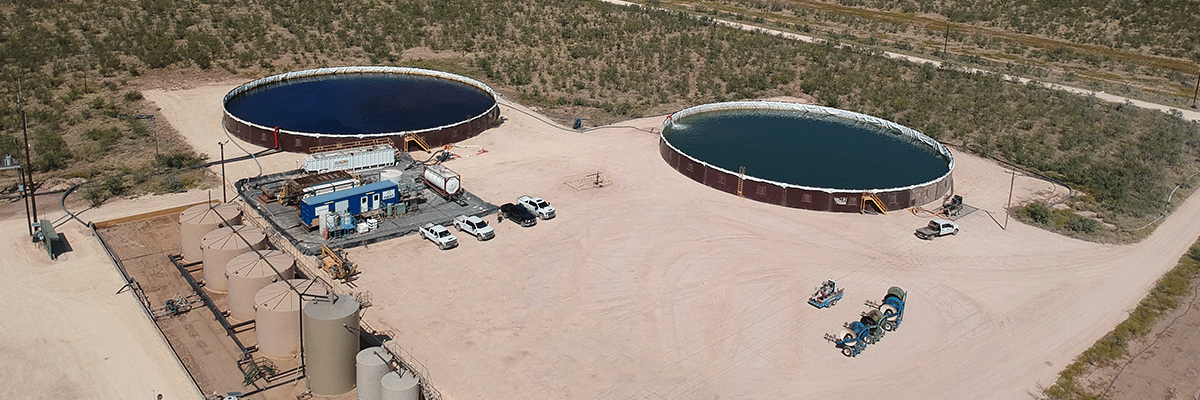

For most operations, the main challenges of recycling produced water are the brininess, the high volumes, and the transfer. Produced water contains a lot of salts and other minerals, so it has to be treated in a specialized way to render it fit for use in fracking. And the treatment program needs to be able to handle high volumes of fluid so as not to be a bottleneck and hinder production from the well. Our SwiftWater Automated Treatment (SWAT™) system, for example, enables recycling in excess of 100,000 barrels of produced water per day using unique technologies and processes that render the water optimal for frac use.

Water transfer is another challenge, one that really brings home the importance of planning and the holistic aspect of a good water management program. On this front, TETRA has the resources to not only provide the industry’s only double-jacketed and quickly deployable lay-flat hose, but also to coordinate access and distribution of water-transfer. Surveying the scattered dispersion of pad sites and storage ponds, TETRA can help operators identify and connect to the most strategically located sources of water, which makes their operations more efficient, economical, and environmental.

Designing for the Optimal

Regarding the design of a water management solution, a comprehensive, holistic approach is best. Instead of sourcing one component from Company X and another from Company Z, partnering with one company, like TETRA, ensures all of the technologies are compatible and overall performance is more efficient, reliable, and economical.

Another feature to further enhance operations is automation. Adding it to remotely monitor and control pumping, treatment, storage, transfer, and blending greatly enhances efficiency and economics and provides visibility and transparency throughout water management activities. Automation reduces the number of personnel needed onsite, as well as their travel to and from the site in vehicles. Our automation solution—BlueLinx™ automated control system—can also apply algorithms to optimize the efficiency of engine pumps to reduce fuel consumption and emissions. Automation also lessens the risk associated with human error and having more workers onsite.

The Market and Long-Term Vision

Given the continued and even rising demand for fossil-fuels, water management is certainly here to stay. As stimulation techniques continue to evolve and steadily enhance to yield more hydrocarbons, we can expect the volumes of water to go up as well. Right now the U.S. water-management market is valued at $12 billion and growing fast, with a compound annual growth rate of 10% expected through 2028. This year recycled produced water will account for 40–42% of the demand for frac-water, up from 39% in 2021 and projected to be 45% in 2024.

Eventually, we want to be able to treat produced water so that it’s suitable for use in other industrial applications, agriculture, and livestock sustenance. Another target is large-scale recovery and commercialization of useful minerals. With our core competency in aqueous chemistry and expertise in extracting minerals and manufacturing products from them, TETRA is ideally suited to pursue these goals, which are realistic and obtainable, not just castles in the air. It’s an age-old cliché but it’s true: invention really is the mother of invention. Water is an absolute necessity, and should be considered a commodity—not traded on any commodity exchange, but nonetheless utterly invaluable to sustain us.

[*] All industry metrics come from Rystad Energy.